Overview

- This world’s first non-contact web tension meter was developed with the goal of proportioning film tension and is equipped on each turn bar to measure pressure between the floating film and surface of the bar.

Composition

- Mechanical: Air turn bar / Air blower / Liquid pump / Silencer / Filter

- Electrical: Pressure sensor / Pressure gauge / Computational display / Motor inverter

Main Unit

-

Tension output Digital display Analog output 4〜20mmA・1〜5V Measurement precision ±1%、full scale (pressure sensor accuracy) Responsivity Within 20ms Measurement availability 1〜1000N/m

Production range

-

Turn bar width : 80〜1000mm / Length 100mm~5000mm Material : Aluminum (Alumite process), SUS-304, SUS-316,Titanium Surface : Stainless reel, Stainless punching Angle : 5〜180 degree Temperature range : 0〜400℃

Use

- Non-contact tension measurement for variety of films / Paper / Metal foils / Fabrics

- Non-contact floating weight measurement for variety of plate materials and products

- Tension distribution measurement (Substrate width direction)

- Multi-concurrent non-contact tension measurement (Post slit)

- Liquid tension measurement

- Liquid tension distribution measurement

Special features

- 1.Non-contact measurement

- 2.Fast response rate

- 3.Micro-hysteresis

- 4.Ultra-low tension measurement

- 5.Small lap included angle measurement

- 6.Parallel non-contact tension measurement

- 7.Non-contact weight measurement

- 8.Intrinsically explosion-proof construction

- 9.Hot spot measurement

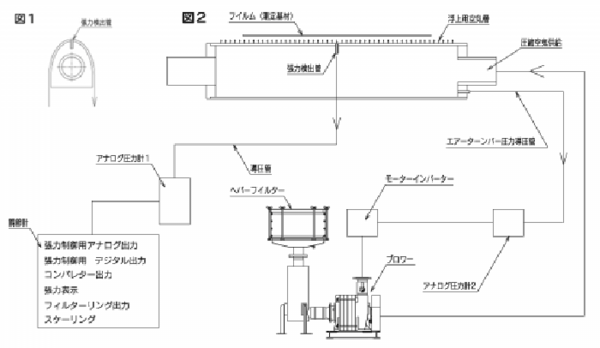

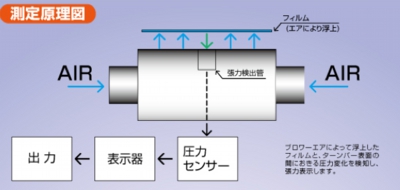

Measurement principle

- Image 1 is a cross section of the Air Turn Bar; Image 2 is a cross section along the width. A tension detector tube is attached to the intermediate vertex along the width of the Air Turn Bar. Inside the bar, the air is supplied from the blower in a pressure range of micro to low 0.5kPa〜10kPa.

- Supplied air pressure level is selected depending on the weight or tension of the substrate. The temperature for the compressed air supply can be set to high for drying or curing.

- As shown in Image 2, the pressure changes when the Air Turn Bar is used to float and put tension on the material.

- 「Lead tube → Pressure sensor → Controllers → Calculation →Tension conversion display → Output → Control indication → Substrate tension control → Tension detector transmission inner pressure change → Transmission 」

- Thus a closed-loop control (negative feedback control) is achieved for electricity and air pressure transmission system. Approximately same system can work for a liquid turn bar.

装置構成図

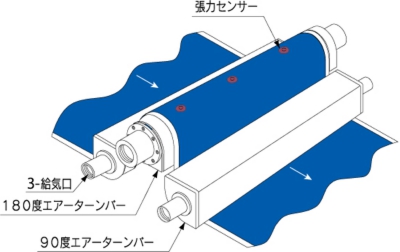

Application example 1

|

|

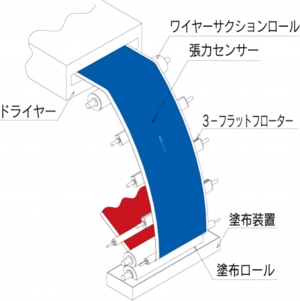

Application example 2

|

|

|

管理者の許諾を得ずに、当サイト内のあらゆる画像や文章をなどの情報を無断転載することは、著作権侵害にあたる行為のため禁止します